This new technology refreshes the limit of photovoltaic power generation possible! SDS digital technology increases power generation by 1%

Dec 06, 2021In November 2020, the National Key Laboratory of Wind Energy and Solar Simulation and Testing and Certification Technology, Beijing Jianheng Certification Center (hereinafter referred to as “Jianheng”), and Huawei Technologies Co., Ltd. (hereinafter referred to as “Huawei”) jointly released the "Inverter With the tracking support intelligent joint control technology SDS (Intelligent Tracking Algorithm) White Paper, SDS continues to improve the efficiency of the photovoltaic power generation system through the synergistic integration of components, inverters, and tracking support. In the era of parity, it provides the industry with an implementation path to further reduce LCOE.

This white paper introduces the development background, technical characteristics and application effects of SDS in more detail, so as to facilitate the industry to have a comprehensive and in-depth understanding of the technology.

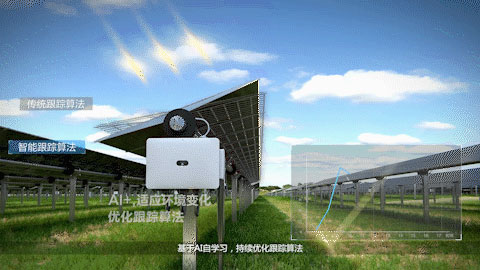

Tracking bracket is a weapon to increase power generation. Using big data and AI technology, the inverter and bracket control linkage to find the optimal angle has become one of the development directions of tracking technology. The SDS technology developed by Huawei, in collaboration with bracket manufacturers and component manufacturers, uses AI technology to further increase the power generation of the tracking system through inverter IV sensing and linkage with the bracket control unit, and closed-loop control.

Huawei SDS technology has the following characteristics:

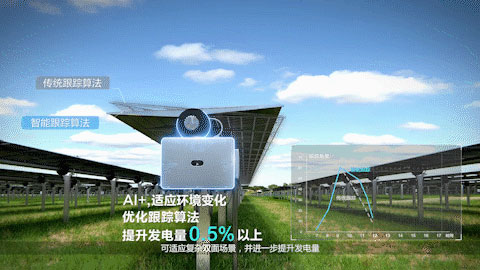

(1) The inverter and the tracking support control system are linked and closed-loop controlled to ensure that the system runs under the state of the largest amount of light received by the components and the best power output;

(2) No need for additional sensing equipment, get rid of manual and experience dependence, use AI technology to automatically sense occlusion and weather change information, and automatically perform tracking angle optimization and control;

(3) Through the inverter integrated tracking support communication and power supply functions, with the help of MBUS technology, reduce the use of tracking support power supply and communication cables.

The Jianheng verification team conducted technical review and comprehensive verification in photovoltaic power plants that actually applied SDS technology, and reached the following conclusions:

(1) The SDS technology developed by Huawei has been verified for a long time and has entered the stage of large-scale application. This technology gives full play to the central role of the inverter, in accordance with the logic of "all-round monitoring or perception of environmental and operating parameters-optimization of tracking angle-maximum and equalization of received radiation-optimization of output parameters" The framework is designed in a scheme, and through closed-loop control with the bracket control unit, the technical efficiency of the tracking bracket is further improved;

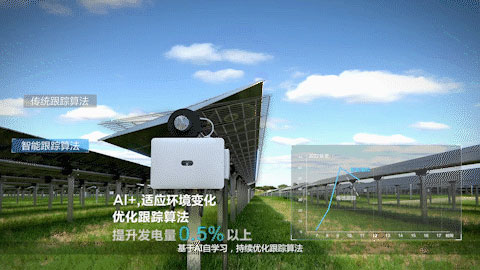

(2) The technical scheme adopted by this technology is scientific and reasonable, and the operation effect is obvious. According to the comparison and verification results of the two sample power stations in the past year, the additional issuance ratio of SDS reached 1.50% and 1.43% respectively; according to the short-term comparison test results, SDS can realize the design function of "automatic monitoring or sensing, automatic optimization and control", and control And the operation effect is in line with expectations, especially in the morning, evening and special weather conditions.

Continuously improving the efficiency of photovoltaic power generation systems is the unremitting pursuit of the industry. Huawei SDS technology, which incorporates AI algorithms, enables the coordinated integration of components, inverters, and tracking brackets. Combining massive power station data and self-learning, it optimizes tracking bracket algorithms and reconstructs power generation. To tap the maximum potential of power stations, Huawei has joined hands with ecological partners such as bracket manufacturers, component manufacturers, and authoritative certification agencies to innovate, so that power stations can generate vigorously throughout their life cycles.