Researchers develop prototypes of solar supercapacitors that can be used in cars to generate electricity and store solar energy

Dec 08, 2021According to foreign media reports, researchers have developed a composite panel that can be used as a photovoltaic cell to use solar energy (000591, shares) to generate electricity, and at the same time as a structural supercapacitor to store energy.

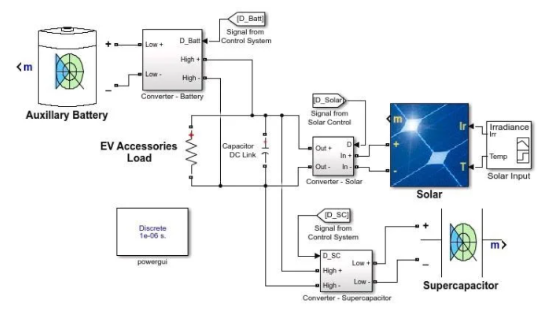

In electric vehicles with ion-exchange rechargeable batteries, these panels can be used for body structures and form a hybrid energy storage system (HESS). Compared with traditional electric vehicles, under solar irradiance of 1000W/m 2, this type of composite board prototype can provide an additional 4.56% of power generation and cruising range per hour.

Use solar supercapacitors as electric car body panels

In electric vehicles, with the help of cost-effective hybrid energy storage systems, several types of renewable energy sources can be integrated to improve efficiency. Among them, compared with fuel cells and electrochemical cells, supercapacitors have many advantages, such as higher power density, shorter charging time and longer cycle life.

It is common to use photovoltaic cells on the roof to collect solar energy. However, using the same equipment to store this type of energy may change the rules of the game in the field of hybrid electric vehicles. Solar Super Capacitors (SSC) are capacitors used to collect and store solar energy.

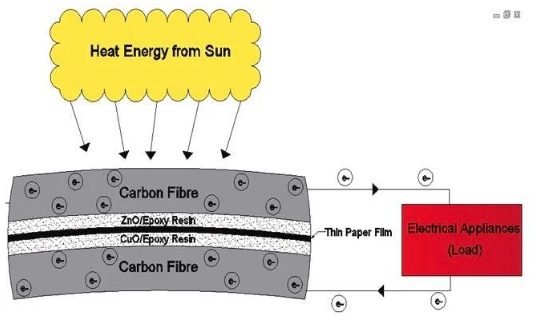

Carbon materials are the most commonly used electrode materials in supercapacitors, and carbon fiber (CF) has proven to be the best candidate material for electric double layer capacitors (EDLC). Benefiting from one-dimensionality, CF has superior charge transport performance. Because of the large number of pores on the fiber surface, CF has a high adsorption capacity for ions. Conductive polymers such as CF and epoxy resin (ER), together with metal oxides such as ZnO/CuO, can be used as high-performance SSC electrodes.

This research

The researchers sandwiched a thin paper film between the ZnO-ER and CuO-ER layers to prepare several prototypes of SSC-based composite boards with different compositions. The paper membrane is soaked in Na2SO4 electrolyte, which can be used as the medium between CF electrodes. In addition, both the ZnO-ER layer and the CuO-ER layer are covered with two layers of CF sheets. In the presence of solar photons, the CF embedded n-type electrode (ZnO-CF) donates electrons, and the CF embedded p-type electrode (CuO-CF) accepts electrons. The two electrodes-ZnO-CF and CuO-CF-, and the electrolyte Na2SO4 form an electric double layer supercapacitor.

CuO can promote electron transfer on the surface of ZnO nanostructures because of its large surface area and high catalytic activity, and it also promotes the reaction process. Therefore, the synthesis of ZnO/CuO-based composite electrode materials helps to shorten the charging time.

The conductive polymer ER makes the nanostructure of ZnO/CuO more compact, so the charge storage time is longer, and will not discharge too fast like traditional capacitors. With the help of conductive polymers, such panels can also use solar energy to convert it into electrical energy.

Observation results

The research team found that as the ZnO/CuO content increased, the conductivity of the SSC sample increased. In addition, the sample with 20gsm paper soaked in Na2SO4 electrolyte has a higher capacitance than the sample with ordinary insulating paper. However, the conductivity of the CF electrode synthesized with ordinary ER is reduced. By increasing the effects of excitons in quantum dots and energy band gaps, special optical effects are generated to promote electron transport and collection, and improve the efficiency of organic SSC.

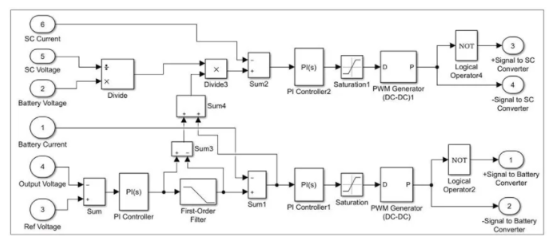

Different performance tests show that the energy conversion efficiency of the optimized sample is 17.78%, the open circuit voltage is 0.79 mV, the current density is 222.22 A/m2, the capacitance is 11.17 μF/cm2, the energy density is 120 Wh/kg, and the power density is 29 kW. /kg.

In the case of solar irradiance of 1000W/m 2, a fully charged SSC can provide an additional 4.56% of power generation and cruising range per hour for traditional electric vehicles. Under the same power output, SSC may reduce the battery size of electric vehicles (model 3) by 10% and reduce the weight by 7.5%.

in conclusion

Researchers have developed an optimized SSC prototype panel for the electric vehicle HEES, which can utilize and store solar energy. The panel energy storage system has a variety of functional characteristics, such as weight reduction, energy storage/on-demand supply, and as an insulator to protect the body from external heat. The electrodes of these SSCs are made of CF, conductive polymers, and metal oxides such as ZnO and CuO.

Sample data shows that this type of HEES can meet the power and energy requirements of electric vehicles and their accessory loads, as well as accurately distribute power among multiple storage systems. These SSCs help to improve the sustainability, cost-effectiveness and energy efficiency of the electric vehicle industry.