Japan's eye-catching black solar cell technology

Dec 23, 2021With the continuous penetration of the concept of sustainable development in various countries around the world, the global solar energy development and utilization scale is rapidly expanding, and various solar-related products emerge in an endless stream. Here are a few new Japanese solar flim end clamp cells.

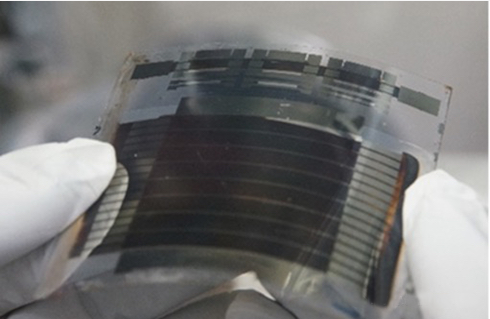

Toshiba announced that as part of the New Energy and Industrial Technology Development Organization (NEDO), it has developed a thin-film perovskite solar cell module with a module area of 703 square centimeters and an energy conversion efficiency of 11.7%. It is said that this battery is currently the largest thin-film perovskite solar cell in the world.

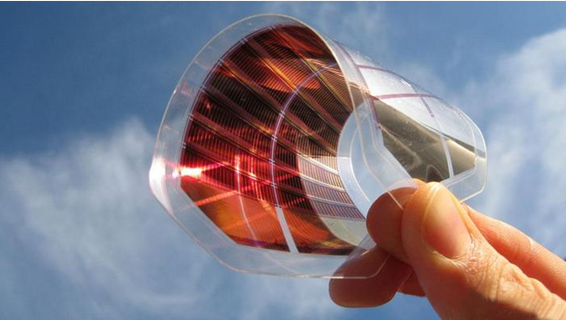

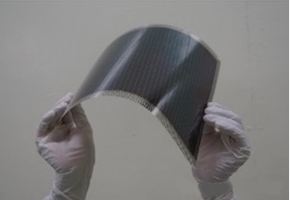

Currently, mainstream crystalline silicon solar cells have limited installation locations due to their weight and shape. Thin-film perovskite solar cells have the characteristics of good flexibility and light weight, and can be installed in buildings with low load-bearing capacity that could not be installed in the past, as well as ZEB (net zero energy building) and ZEH (net zero). The form of installation, such as installation on the wall, to achieve a zero-energy house. In addition, as next-generation solar cells, they are attracting attention due to their low-cost materials, which can be formed by coating and printing, and can achieve low-cost manufacturing.

On the other hand, although the energy conversion efficiency of a small area cell (0.09 cm2) has been proven to be 22.7%, which is close to that of a crystalline silicon solar cell, it is difficult to form a uniform thin film with a larger area.

In this case, in addition to the "meniscus coating technology" that uses the meniscus (curved surface formed by the liquid in the gap), Toshiba has also developed a new manufacturing process, specifically, through the development of large Area coating process and design ink composition to control the reaction of lead iodide and methyl ammonium iodide on the substrate. A large area and high efficiency are realized.

In addition, by controlling the coating process and optimizing the perovskite crystal growth conditions, the uniformity of the large-area in-plane film and the uniformity of the crystal film quality have been successfully improved. As a result, even 703 cm2 has obtained a conversion efficiency of 11.7%, which is close to the practical module (900 cm2) and one step closer to practicality.

In the future, with the goal of realizing a practical module size, the technology will be further developed and the area will be expanded. In addition, by improving the material of the perovskite layer, Toshiba plans to strive to achieve high efficiency comparable to that of crystalline silicon solar cells.

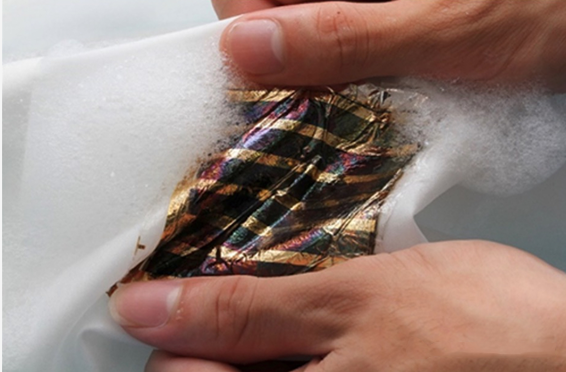

The joint research team used the new semiconducting polymer "PNTz4T" developed by the RIKEN Emerging Molecular Function Research Group in 2012, and used a polymer material with a thickness of about 1 micron to fabricate an organic solar cell with an inverted structure. Manufactured on a specific parylene substrate. This ultra-thin organic solar cell has a short-circuit current density (JSC) of 16.2mA/cm2 and an open-circuit voltage (VOC) of 0.71V. Under simulated sunlight, it is filled and peeled from the glass support substrate with an output power of 100mW/cm2. A factor of 69% and an energy conversion efficiency of 7.9%.

Compared with the currently reported 4.2% efficiency of highly flexible organic solar cells, it is said that the efficiency will be nearly doubled. In addition, it is confirmed that the device can be driven stably even if it is crushed to about 50%, and has extremely high mechanical flexibility.

It was also found that the produced ultra-thin organic solar cells had high water resistance, and even after being immersed in water for 5 minutes, the energy conversion efficiency hardly decreased. In addition, even if the surface of the device is soiled by a black water-based pen, if the surface of the device is immersed in a detergent solution or stirred to remove the surface of the device, energy conversion will not occur, and the performance of the device will not decrease. It is said that the efficiency can be restored to the initial value.

In addition, a sealing technology has been developed to achieve elasticity and water resistance by sandwiching an ultra-thin organic solar cell with a thickness of 3 microns between two pieces of rubber that have been pulled out in two directions in advance. After the non-rubber sealing device is immersed in water for 120 minutes, the energy conversion efficiency is reduced by about 20% from the initial value, while the energy conversion efficiency of the rubber sealing device is only reduced by 5%. In addition, even if there are water droplets that repeatedly expand and contract by about 50%, the energy conversion efficiency can maintain 80% of the initial value.

Realize the "window of power generation"

The company is cooperating with Yamagata University and others on the research and development of organic thin-film solar cells. One of its characteristics is that an almost transparent organic thin-film solar cell is realized by using a special transparent material as the anode. The smart power window takes advantage of this function and aims to become a “power window” that allows you to see the scenery outside.

The intelligent power window uses 96 organic thin-film solar cells of 50 mm square. The organic thin-film solar cells are sandwiched between transparent acrylic panels, which are attached to the interior of the building. Because it can block ultraviolet and infrared rays, it also has the effect of preventing indoor furniture from fading due to sunlight.

Currently, the smart power generation window has been demonstrated as a window for the "Smart Future House", an organic electronics demonstration facility opened by Yamagata University in Yonezawa City, Yamagata Prefecture, and the company is continuing to verify power generation. So far, it is said that it generates about 3Wh/hour of electricity per day on average.

The power generation efficiency of the developed organic thin-film solar cell is about 3.5% at the highest, and the transparent type is about 2%. Although the power generation is not large, it is said that it will continue to increase in the future. At present, the commercialization time of organic thin-film solar cells has not yet been determined, but taking advantage of its thinness, low cost and transparency, it is considering future cooperation with building material manufacturers for commercialization. In addition, the company is developing organic thin-film solar cells that can be applied to flexible curved surfaces, and plans to expand the application range of solar cells.